All our facilities are ISO14001:2015 certified to ensure our Environmental Management Systems are robust enough to be competitive in the industry.

In every facility, we are running a problem-solving methodology to achieve reduction in GHG emissions, water withdrawals, and waste production. Some of our most relevant actions are:

To counter water scarcity at Apodaca Plant, we have implemented water reuse practices in our painting processes, reusing up to 26% of treated water through reverse osmosis.

At our Roanoke Plant, we have achieved a remarkable 100% zero-waste-to-landfill policy. Through recycling, reusing, and innovative waste-to-energy solutions, we minimize our environmental impact while conserving natural resources.

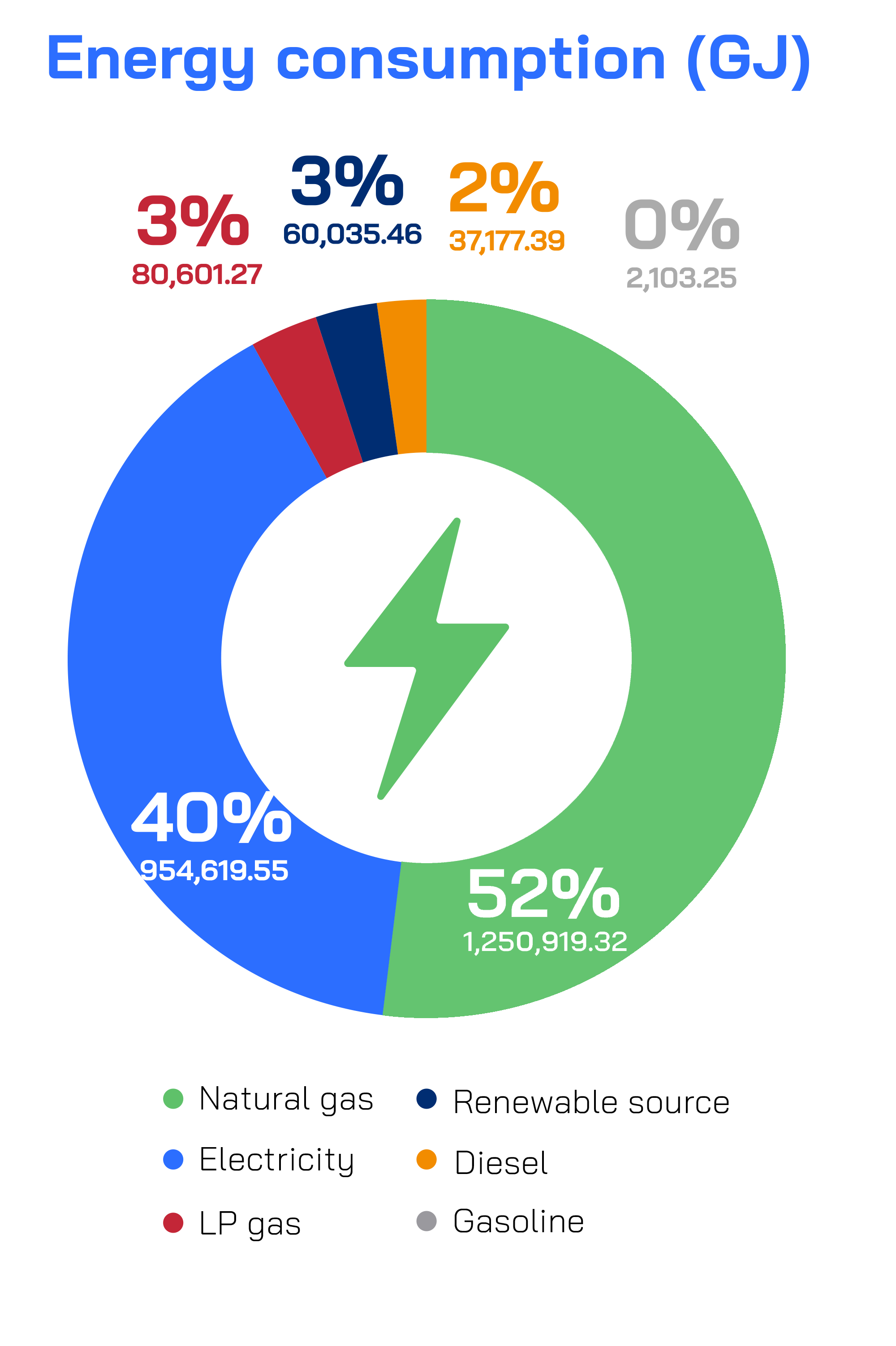

At Saltillo Plant, we are undergoing a LP gas-to-electric forklift transition. In 2022, we replaced 80% of our forklifts, resulting in a 93% decrease in our Scope 1 CO2 emissions related to the internal movement of materials and finished goods.

2Scope 1 emissions include: diesel, gasoil, gasoline, natural gas, propane (LPG / liquid) and welding gases.

Considers information from Mexico, United States, Brazil, Argentina, India and Thailand sites.

3Data assured by ERM CVS. Please see the ERM CVS Assurance Statement.

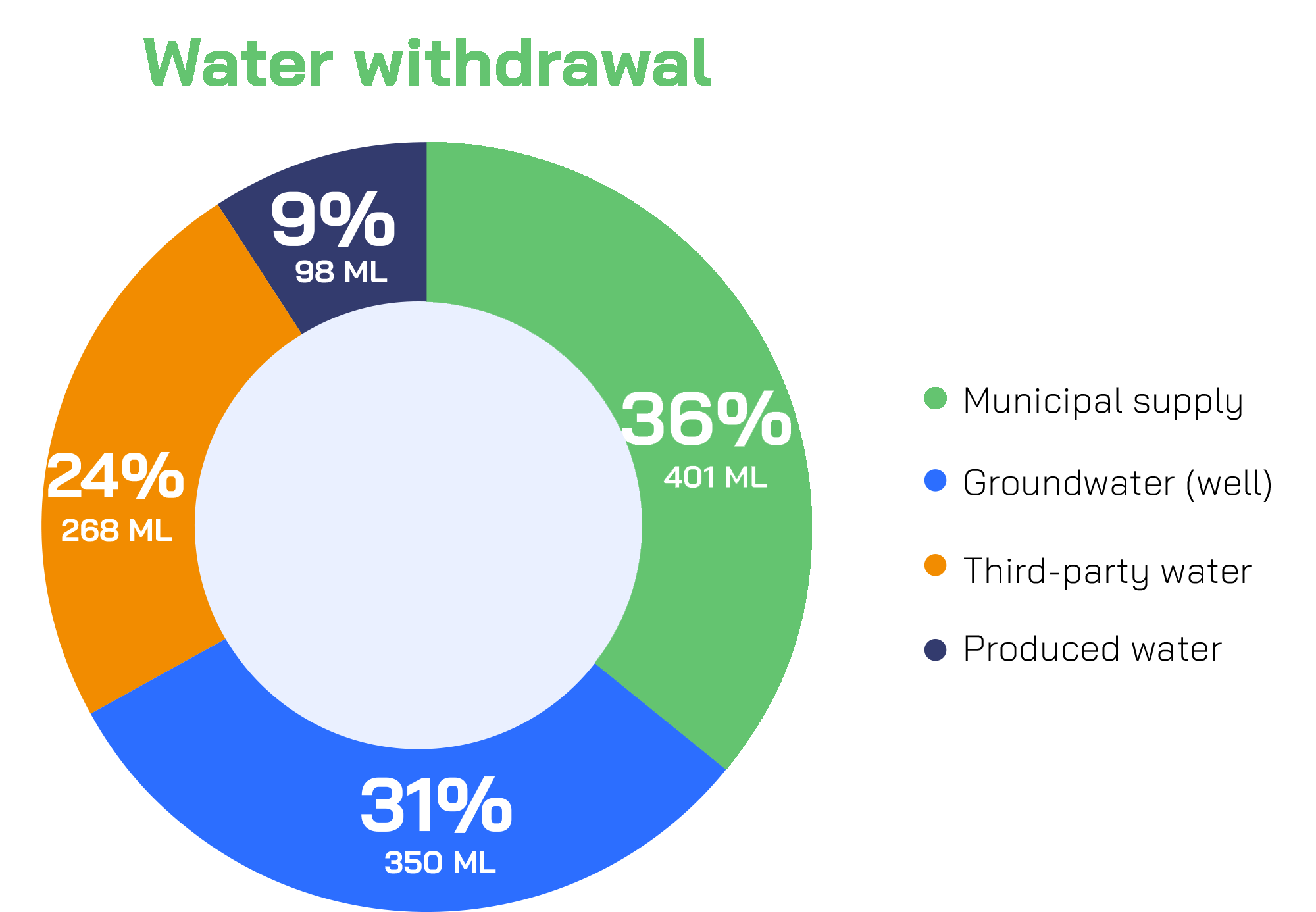

We identify the sources of water withdrawal (mainly municipal, well, and/or purchased industrial water) of our operations, accounting for those on each of our manufacturing plants.

We mainly use water during the painting process, except in those plants that either do not have this procedure or they carry it out without water. Besides that, it is used in bathrooms, kitchens and irrigation of green areas. Overall, all water used is directed to an internal treatment plant prior to discharge. In compliance with local legislation, we carry out periodic chemical analysis at all facilities to measure our water discharge quality.

Occasionally, we prepare an environmental matrix to clearly identify our industrial activity footprint on water resources. Moreover, we develop and implement action plans to mitigate identified impacts that include awareness campaigns, trainings, and water consumption reduction projects. We define goals based on the past year’s performance, always seeking to reduce our water extractions in relation to each plant’s sales.

In 2023, we will implement a Water Stewardship Program to establish context-based objectives.

ML: Megaliters

(1 ML = 1 million liters)

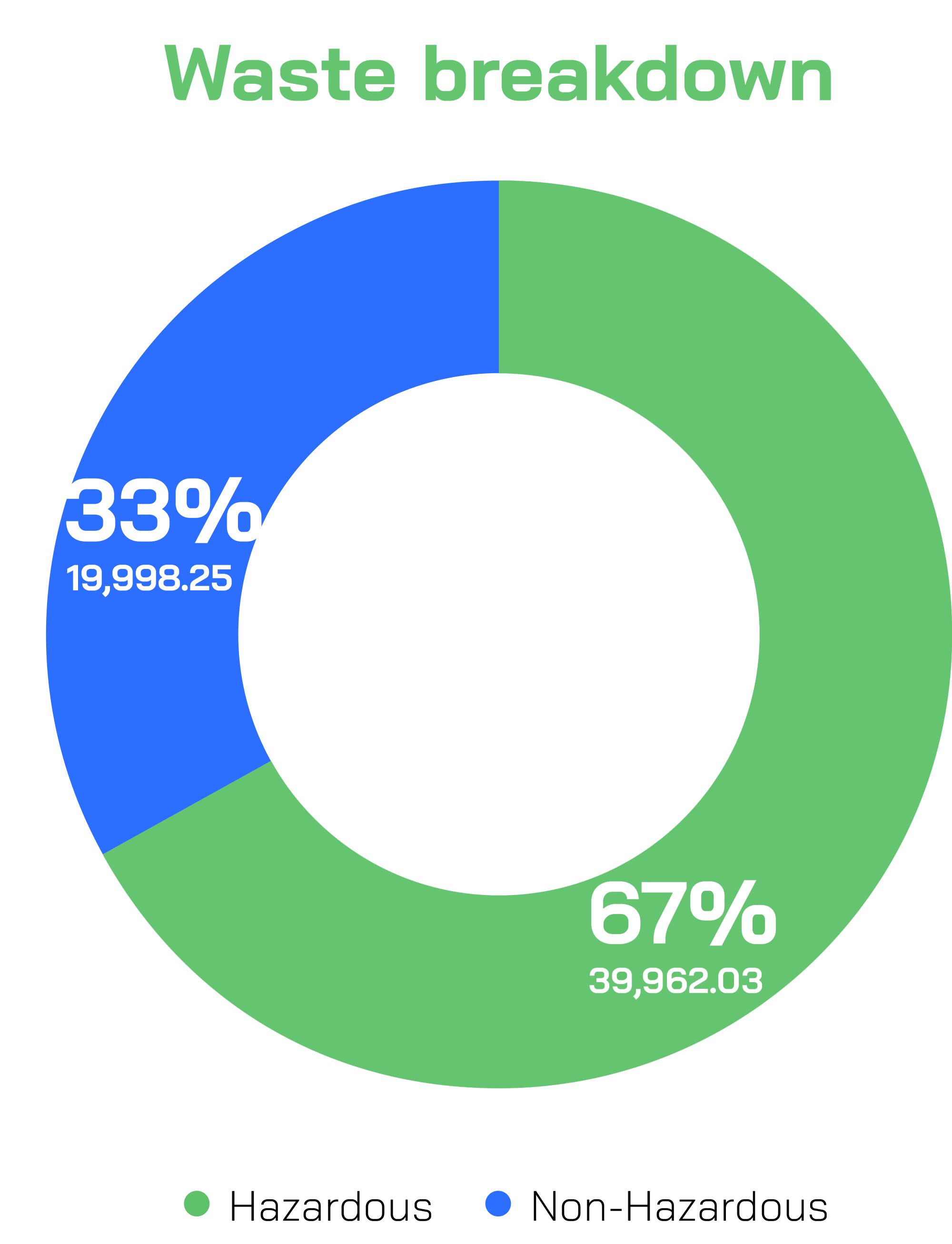

Each manufacturing site has its own process regarding waste management according to local legislation. Overall, we monitor the total waste production, including operational and supporting processes (offices, cafeterias, warehouses). We classify waste as hazardous and non-hazardous; the latter is divided into confined and co-processed while the former is divided into recycables and landfill one, separating it more consistently and arranged according to each plant’s country/city regulation.

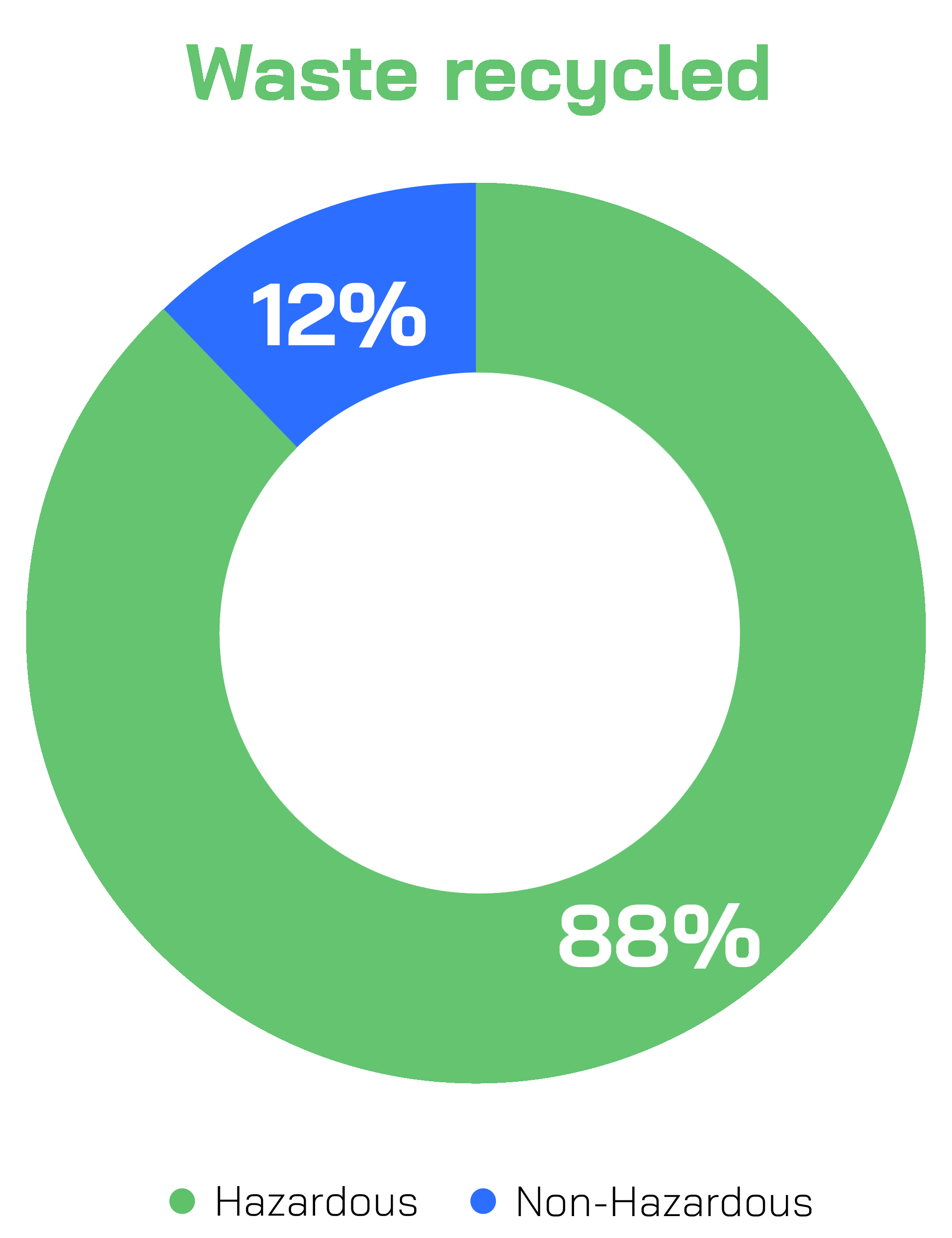

At our Roanoke Plant, we have achieved a 100% zero-waste-to-landfill policy where everything such as PET, cardboard, aluminum, wood, scrap steel, and the used shot and used shot dust is recycled and reused. In addition, general waste is incinerated to generate “waste to energy”, strongly mitigating the environmental impact of our operation and contributing to the conservation of natural resources.

*Only Roanoke plant sends its hazardous waste to a third-party recycler. All non-hazardous waste recycling is carried out in our facilities, whether offsite or onsite, depending on the plant.